Recently, the folks at Harvard’s Wyss Institute and Harvard SEAS (The John A. Paulson School of Engineering and Applied Sciences) started playing with 3D printed electronic components.

The results have led to many applications of bio-inspired technology, the ramifications of which will help blur the lines between biology and technology in the near future.

As the greatest minds of our time debate the coming singularity when humans and machines meld into one, the march of the technology which will make this all possible progresses quietly in the research labs of great institutions.

It is in fact, a work in progress, one we can see happening if we open our eyes. With their recent work, Harvard has taken humanity one step closer to the singularity.

Wyss Institute & The SEAS

Wyss lab | youtube

Wyss Institute is the new kid on the Harvard research block. It is the meeting point between many disciplines within the university, medicines, arts, and sciences.

The researchers from Wyss turn brilliant ideas into marketable ones, thus their connection to the SEAS on this project.

From their site:

“The Wyss Institute develops groundbreaking bioinspired technologies, ranging from devices and materials to high-value therapeutics and diagnostics, and it works to translate them into commercial products that will bring about positive near-term impact world-wide”

The SEAS has been around since 1857, an engineering school within the walls of the prestigious University. The school offers graduate and undergraduate degrees in engineering and applied sciences.

They’re the researchers behind products like black silicon, high-speed nanowire circuitry, light-focusing optical antennas, and an engineered weathering process that might mitigate climate change.

The list of high-profile, accomplished graduates is staggering.

Soft Electronics

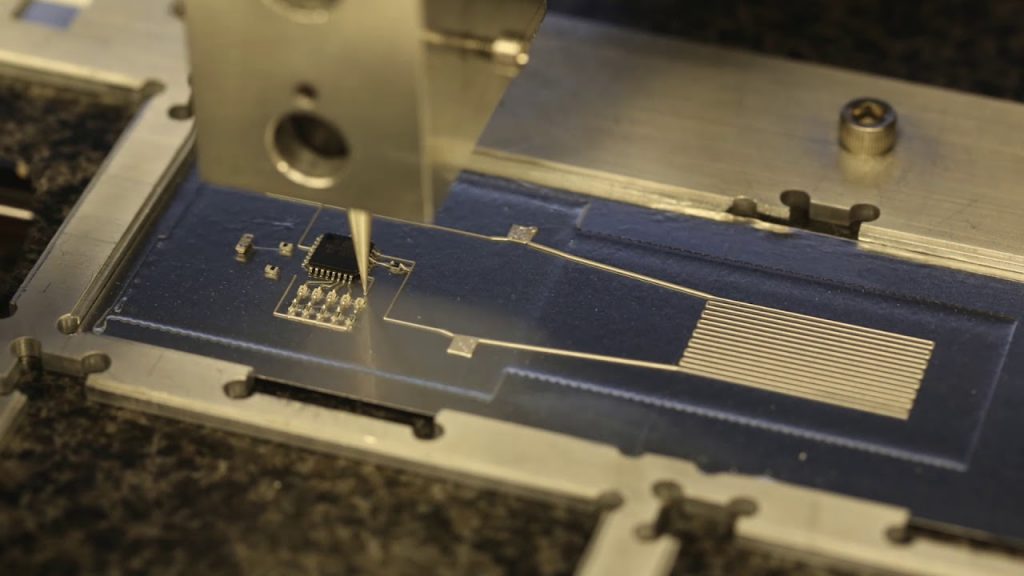

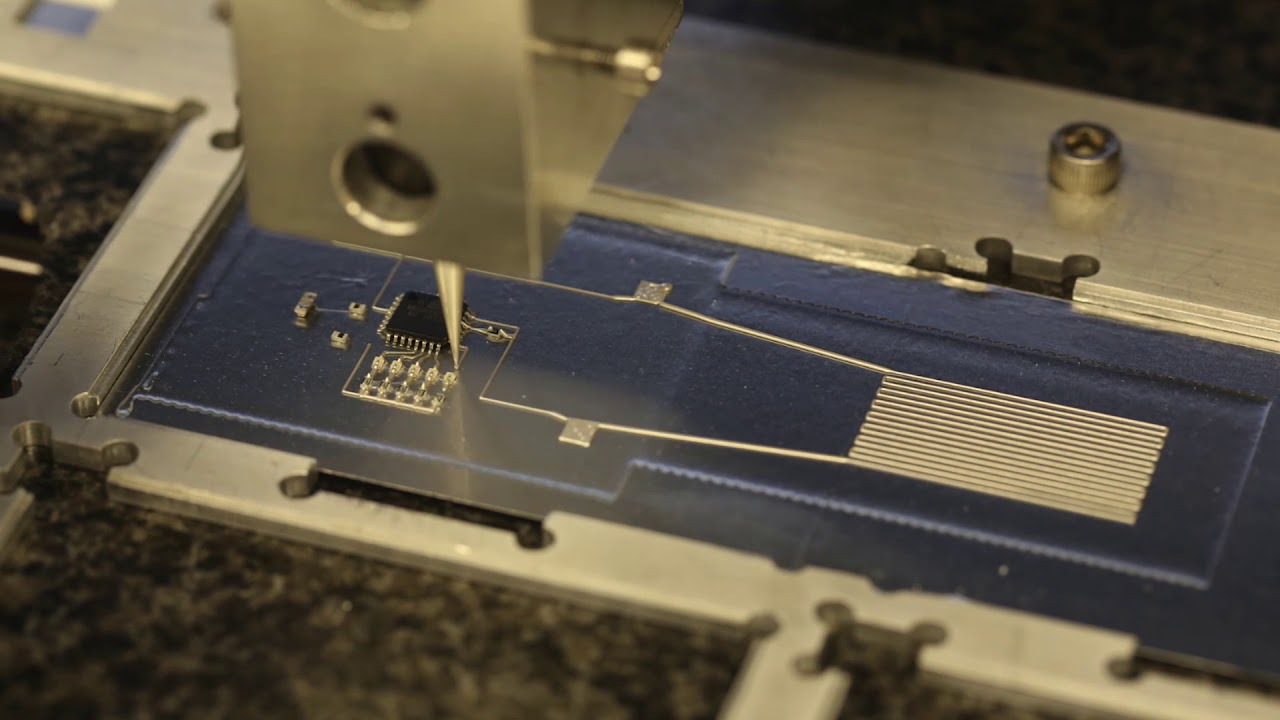

These folks at Harvard have combined what we know about existing 3D printing technologies to develop flexible metal elements, blending them with hard elements to make what they call, “soft electronics.”

The problem with traditional electronics is that we can’t wire directly into the human nervous system. The body builds up scars tissue over time, eventually breaking the connection.

Our best efforts always fail. We’ll come back to how Harvard’s newest tech might bridge that gap.

The other issue is malleability of modern electronics. When one bends metal parts (wires) enough times and they break.

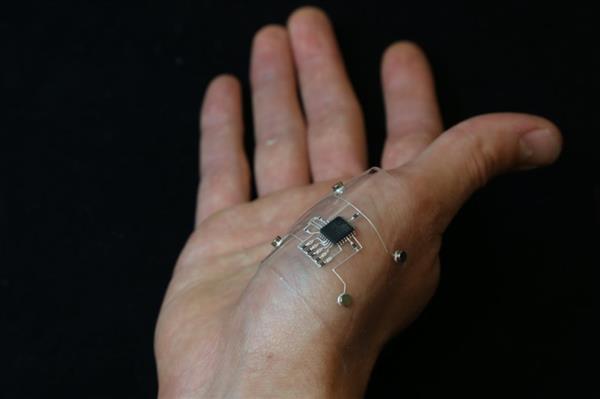

It’s the invisible wall between modern wearables and human body. Wearable technology today must exist as non-integrative accessory, worn on the skin.

The best we can do is equip wearables with sensors, which read the body at the level of the skin with varying levels of accuracy. Those wearables may have silicon parts, like wristbands and such, which allow the wearable to stay on the body.

They exist as vehicles for carrying technology, not for integrating it. But, by fusing the silicon aspects with flexible metals, our wearables could become more integrated.

Hacking the CNS

The Harvard researchers, as they should be, are more concerned with how they can apply that technology today.

One suggested application is across human joints to measure strain. When stretched, the electronic pathways of these stretchable sensors increase in resistance.

Think of it slowly like closing off the opening of a waterpipe. The water would slow down on one side, but speed up on the other, creating massive tension at the constriction. That’s resistance.

Today, the tech from Harvard can measure that increased resistance, demonstrating the change with LED lights. One assumes they could also translate that into a scaled readout on a smart device.

There could be an application for this in wearables, one for athletic performance and joint pressure. This writer, however, speculates that there is more to this idea than clever joint-measuring wearables.

Pushed to a microscopic level, could future researchers build custom-designed interfaces for crossing the CNS-wearable barrier? If we could manufacture microscopic flexible material, genetically-programmed to scan as non-foreign, would the body be less likely to create scar tissue?

No doubt this is way beyond this blogger’s education, a wild dream, but someone is going to have to bridge this gap at some point.

We will eventually create technologies which are more bioinspired, not unlike what the brains at Harvard created. Every innovation we have is either born from serendipity or the great ideas of researchers before us.

nakedsecurity.sophos.com

Sources: coolwearable.com vimeo.com